Cutting Optimization Pro : Version 5.18.0.71 (Software)

Cutting Optimization Pro 5.18.0.71

Cutting Optimization Pro : Version 5.18.0.71 (Software)

Introduction:

Cutting Optimization Pro : Version 5.18.0.71 (Software). Cutting Optimization Pro 5.18.0.71 is a powerful software solution developed for the optimization of the cutting process in various industries dealing with the cutting of materials such as wood, metal, glass, and textiles. It is also being highly utilized by professionals and enterprises in manufacturing, construction, and woodworking to reduce material waste and enhance their productivity. This software has grown into a go-to tool for companies dependent on efficient material cutting processes, focusing on the provision of state-of-the-art algorithms for precise optimization.

This software targets enterprises that need to make the most of their raw materials, be it for creating furniture, metal products, or custom orders with exact measurements. Cutting Optimization Pro takes all the guesswork out of the cutting plan, allowing businesses to be more cost-effective and reduce waste to improve operational efficiency. With this software, automation eliminates human error altogether, ensuring the best cutting patterns are chosen.

Description:

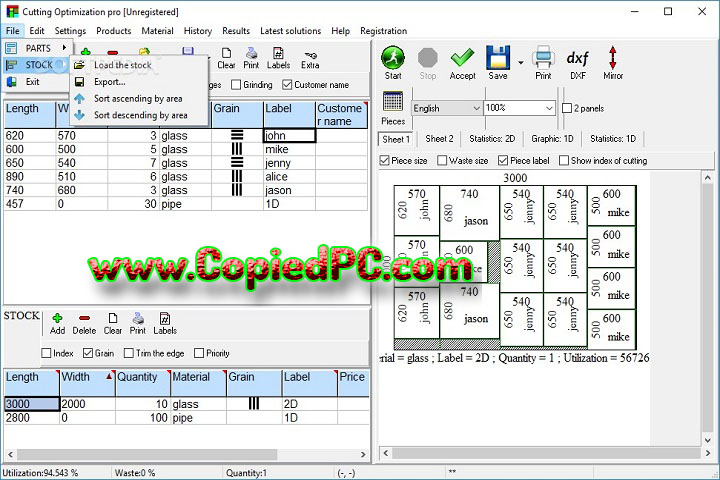

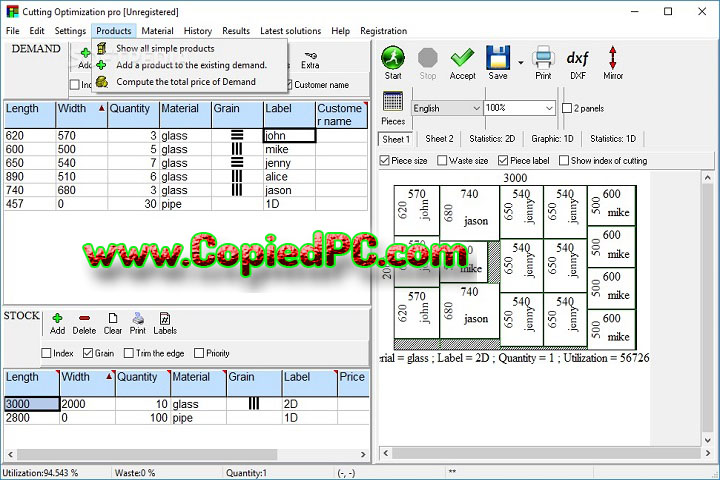

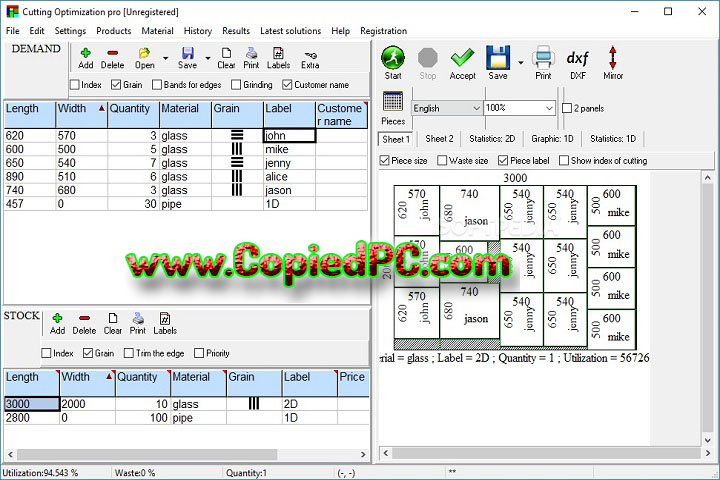

Cut Optimizer Pro 5.18.0.71 will enable users to create optimized cutting plans for everything from sheet goods to rolls of material. The tool is based on a strong algorithm for cutting optimization that will automatically generate the most efficient cutting patterns. This minimizes waste, saves time, and reduces costs. It works by taking input data from a user on material dimensions, the requirement of cuts, and desired size of output; then, generating the cutting plans according to the specifications.

You may also like :: XRecode : Version 3 v1.158

Another great advantage of working with Cutting Optimization Pro is solving complex cutting tasks. It calculates the most effective consumption, considering a number of factors such as material thickness, grain direction, and the type of cut required. It also includes handling remnants, which means every single piece of raw material can be optimized.

No matter if one is working with rectangular, circular, or irregularly shaped materials, the software Cutting Optimization Pro can assist businesses in creating more accurate, faster, and more cost-effective cutting plans. The tool could be useful in various industries like wood, metal, glass, among others, and is the ultimate tool to be implemented by a company in an attempt to automate its production process.

Overview:

Cutting Optimization Pro 5.18.0.71 solves cutting problems for a number of industries by offering complex software suites to solve such problems. By automating the optimization of a cut, it will simplify a user’s task when creating a cutting plan or making precise decisions about exactly how to cut his material. Advanced algorithms calculate how to obtain the best cuts to help the company minimize waste, enhance production times, and ensure the most economical material use.

It has several ways of cutting, from a simple line cut to complex angular cuts and compound angles of cutting. Therefore, this tool can be applied to various business types, considering the work with different materials. Its user-friendly interface, combined with its strong features, will suit small and large-scale businesses that need efficient solutions in the area of cuts.

You may also like :: WinTools.one Pro : Version 24.11.1

Software Features:

Versatility across a range of materials and industries.

Advanced cutting optimization algorithms.

Easy integration with other software and tools.

Greater accuracy with minimal waste of materials.

Reports and documentation to the users in detail. Software Features

Cutting Optimization Algorithms At the core of this software is an advanced cutting optimization algorithm, which enables the software to generate an efficient cutting plan by minimizing waste and maximizing material usage. The algorithm considers a variety of factors, such as material dimensions, cut types, and machine constraints, to come up with optimal cutting plans for any given set of input parameters.

Be it from rectangular sheets, irregularly shaped materials, or any other material requiring a certain way of cutting, the feature saves time and resources in the simplification of cutting.

Material and Machine Customization: Cutting Optimization Pro enables users to customize material dimensions, thicknesses, and grain direction to create accurate cutting plans. This tool supports a wide variety of materials, including wood, metal, glass, and other sheet goods. Users can input the specific characteristics of the material they are working with, such as thickness and width, and the software will automatically adjust the cutting patterns accordingly.

Software Features:

It also includes machine configuration options, which allow businesses to set machine limitations on such things as the length of a cut, the number of blades, and specific cutting speeds. This ensures that the generated cutting plan is customized for the business’s machinery, ensuring accuracy and minimizing errors.

Advanced Reporting and Documentation: Perhaps one of the most valued features of the Cutting Optimization Pro is the generation of detailed reports and documentation. The full cutting reports created by the software include, but are not limited to, material use, number of cuts, number of pieces produced, and so on. This gives a business the ability to track and trace their material usage, monitor efficiency, and provide detail in documentation for quality control and record-keeping purposes.

You may also like :: WizTree : Version 4.22

Besides that, reports can be tailored with a lot of specific details needed, like material costs, cutting time of the parts amongst many others, to give enterprises very clear overviews of their own productions. This feature is essential as far as ensuring transparency into the operations is concerned, thus offering grounds for which businesses seek and find opportunities for process enhancement.

Support for Complex Cutting Patterns: From linear, angular, and compound cuts, Cutting Optimization Pro is designed to support a wide range of cutting patterns. It’s thus suitable for businesses that must perform intricate or non-standard cuts. Be it sheet material with straight cuts, beveled edges, or some custom cutting angle, this software can handle it.

Software Features:

This program’s flexibility allows users to design cutting plans that are tailored to highly specific requirements, minimizing manual adjustments and rework. It is a tool of great importance to those industries that need cuts in high precision, like in the woodworking or metal fabrication sectors.

Inventory Management and Remnant Handling: Cutting Optimization Pro provides features related to inventory management and remnant handling. The software tracks the usage of materials and logs the unused remnants of materials that can be used in other projects. This feature helps a business to make the most out of every piece of material to eliminate waste, thus reducing overall material costs.

Remnants are kept in the system for easy retrieval and re-usage, hence saving business inventory and the cost of raw materials.

User-Friendly Interface Despite the strong capabilities, Cutting Optimization Pro maintains an intuitive interface that is easy to work with. Its intuitive design lets even a completely inexperienced user master the software without extensive training. The clean layout of this program and logical organization of tools and options enable one to generate cutting plans without an uncomfortable learning curve.

Software Features:

Besides, the drag-and-drop functionality of the software and visual aids allow users to enter material dimensions quickly and, at the same time, make real-time adjustments to the cutting plan. Such ease of use means businesses can focus on the task at hand, not wrestling with complex navigation within the software.

Batch Processing and Automation: Cutting Optimization Pro allows for batch processing, which can be used to optimize many cutting plans at once. In this respect, it is very helpful in companies with large volumes of orders or projects. Using batch processing, it can create the cutting plan for various materials or designs automatically and thus save time and minimize manual effort.

Automation helps to speed up the planning and execution of the entire process of cutting, hence perfect for high-volume production.

System Requirements:

The following are minimum system requirements to successfully install and run the Cutting Optimization Pro 5.18.0.71:

Operating System:

Windows 7/8/10 32-bit or 64-bit

Processor:

Minimum: Intel Core i3 or greater processor

Recommended: Intel Core i5 or higher, for ideal performance.

Memory:

Minimum: 4 GB RAM

Recommended: 8 GB or more, so that many large projects can be taken up with much better performance

Storage:

Minimum: 200 MB free disk space for installation

Any extra space needed for the storage of the project files and reports. Graphics: Any standard graphics card capable of displaying 16-bit color or greater (1024×768 resolution or better) Additional Software Microsoft.NET Framework 4.5 or higher

Download Link : Here

Your File Password : CopiedPC.com

File Version & Size : 5.18.0.71 | 2 MB

File type : compressed/Zip & RAR (Use 7zip or WINRAR to unzip File)

Support OS : All Windows (64Bit)

Virus Status : 100% Safe Scanned By Avast Antivirus